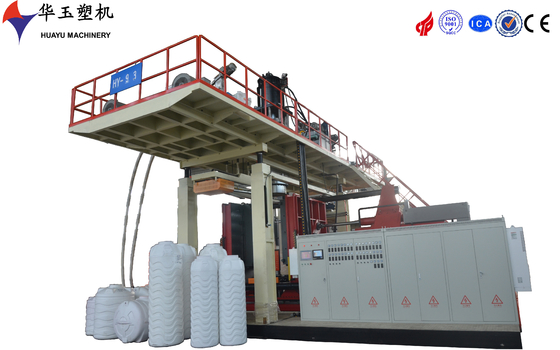

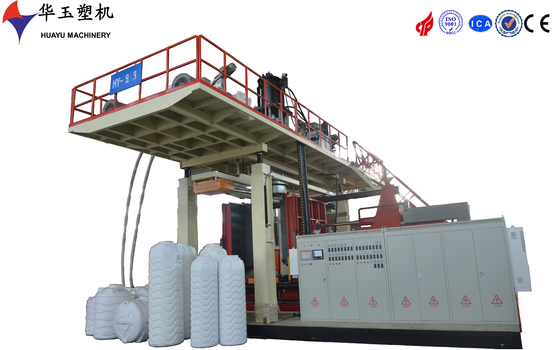

2000L 4-laags grote heavy-duty water tank blaasmachine

| Capaciteit | 500-1000 liter | Toepasselijke industrieën | Ander |

|---|---|---|---|

| Typ van blazen | Extrusieblaasgietwerk | Besturingssysteem | Semi-automatisch |

| Parisoncontrole | MOOG 200punten | Maximale vormgrootte | 1200 x 1000 mm |

| Luchtschakelaar | Schneider | Totaal vermogen | 560 kW |

| Productiecapaciteit | 50-60 stukken/uur | Reinigingsmethode | Het gemakkelijke Schoonmaken |

| Drukcilinder | 1700*1800 | Controleur | PLC+touchscreen |

| Machinedimensie | 15*9*12 | Machinetype | Uitdrijvingsslag het Vormen |

| Garantie | 1 jaar | ||

| Markeren | 2000L water tank blaasmachine,4-laags heavy-duty blaasmachine,grote water tank vormmachine met garantie |

||

Deze 2000L vierlaags heavy-duty blaasmachine is ontworpen voor de productie van ultra-hoogwaardige meerlaagse kunststof producten. Het quad-layer co-extrusiesysteem maakt geavanceerde materiaalcombinaties mogelijk, wat zorgt voor verbeterde barrière-eigenschappen, verbeterde productduurzaamheid en superieure mechanische sterkte. Het heavy-duty watertankkoelsysteem zorgt voor efficiënte warmteafvoer en handhaaft optimale bedrijfstemperaturen, waardoor de productie-efficiëntie wordt verhoogd. Het geavanceerde besturingssysteem van de machine biedt precieze controle over het vormproces, wat zorgt voor consistente productkwaliteit. Het duurzame ontwerp en de betrouwbare prestaties maken het geschikt voor industrieën die grote, meerlaagse kunststof producten vereisen. Het watertanksysteem is ontworpen voor eenvoudig onderhoud en langdurige betrouwbaarheid, waardoor deze machine een kosteneffectieve en efficiënte oplossing is voor uw productiebehoeften.

|

Opspannen Systeem |

||

|

plaatgrootte |

1900*2000*60mm (B*H*D) |

soepel lopend, geen lawaai; de spankracht is groot |

|

spanklep |

200+280*2 |

|

|

slag van de spanklep |

2000mm |

|

|

spankracht |

1800KN |

|

|

afstand tussen platen |

1000-3000mm |

|

|

max. matrijsgrootte |

1600*2000mm (B*H) |

|

|

blaas- en koelsysteem |

||

|

rek slag |

afhankelijk van de producten |

|

|

blaaspen op/neer slag |

600mm |

|

|

luchtzitting slag |

400mm |

|

|

maximale luchtdruk |

0.8Mpa |

|

|

verbruik |

2.3m3/min |

|

|

Koelmethode |

Circulerend water |

|

|

Waterdruk |

0.3MPa |

|

|

Koelwaterverbruik |

60m3/u |

|

![]()