Alle producten

250L capaciteit Double-Ring Drum Blow Molding Machine met 30:1 L/D-verhouding en energiebesparende werking

Productdetails

| Schroefdiameter | 150MM | L/D | 30: 1 |

|---|---|---|---|

| Schroefmateriaal | 38CrMoAlA,nitrideren | Uitvoer | 30 STKS/u |

| Luchttoevoer | 0,8×6 (MPa × kubieke meter per minuut) | Totaal vermogen | 324,5 kW |

| Gemiddeld energieverbruik (AEC) | Ongeveer 180 kW per uur | ||

| Markeren | Trommelblaasvormmachine met een capaciteit van 250 liter,Blaasvormapparaat met een L/D-verhouding van 30:1,Energiebesparende werking Blaasvormer met dubbele ring |

||

Productomschrijving

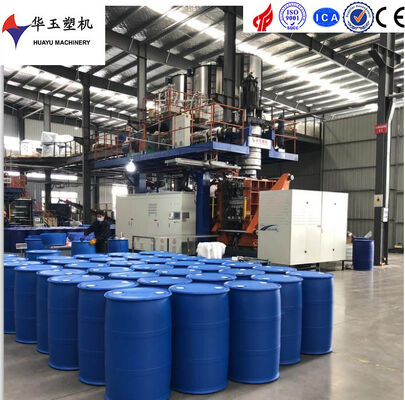

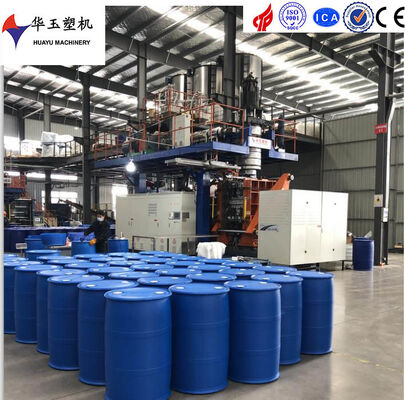

250L 1-laag dubbel-ring trommel blaasgietmachine

Belangrijkste voordelen

- Hoge productie-efficiëntie:Snelle cyclustijden en continue gietcapaciteit leveren 50+ 250L dubbelringdrums per uur, waardoor de productieopbrengst voor grootschalige productie aanzienlijk wordt verhoogd.

- Precision Molding Performance:Een geavanceerd servo-besturingssysteem en een nauwkeurig ontwerp van de matrijskop zorgen voor een uniforme wanddikte en consistente dubbele ringstructurele afmetingen die voldoen aan strenge industriële normen.

- Energiebesparende operatie:Energiezuinige motoren en warmtehersteltechnologie verminderen het energieverbruik met 15-20% in vergelijking met traditionele machines, waardoor de exploitatiekosten op lange termijn worden verlaagd.

- Gebruikersvriendelijke werking:Intuïtieve touchscreen HMI met vooraf ingestelde gietparameters minimaliseert de trainingstijd en vereenvoudigt de dagelijkse productie aanpassingen.

- Duurzame uitrusting:Het hoge-sterkte stalen frame en slijtagebestendige componenten zorgen voor een levensduur van meer dan 10 jaar met minimaal onderhoud.

- Versatile compatibiliteit:Geoptimaliseerd voor 250L 1-laag dubbelringdrums, maar verstelbaar voor verschillende kunststofmaterialen (HDPE/PP) en vaten van vergelijkbare grootte.

- Stabiel dubbelringvorming:Een speciale vorm- en luchtdrukregelaar zorgt ervoor dat de ringen een sterke draagkracht hebben zonder vervorming en voldoen aan de eisen van stapelen en transport.

- Laag materiaalafval:Precieze materiaalvoeding en geoptimaliseerde parisoncontrole verminderen het plasticschrootpercentage tot minder dan 3%, waardoor de grondstofkosten dalen.

Energieconfiguratie specificaties

| Component | Specificatie |

|---|---|

| Extruder aandrijving | 160 kW Siemens onafhankelijke luchtkoeler |

| Motorvermogen van het hydraulisch hoofdsysteem | 35.6KW Huichuan servomotor |

| Motorvermogen voor wanddiktecontrole | 7.5 kW |

| Verwarmingsvermogen van het extruderingssysteem | 7 stuks * 7 kW/stuks |

| Verwarmingsvermogen | 7 stuks * 6 kW/stuks |

| Air Supply | 0.8*6 (MPa * kubieke meter per minuut) |

| Koelwaterverbruik | 0.3*20°*30 (MPa * graad * kubieke meter per uur) |

| Totaal vermogen | 324.5 kW |

| Gemiddelde energieverbruik (AEC) | Ongeveer 180 kW per uur |

Deze industriële blaasgietmachine is ontworpen voor de productie van grote hoeveelheden 250L dubbelringdrums.combinatie van precisie-engineering met energiezuinige werking voor een optimale productieprestatie.

Geadviseerde Producten